Our work

The most important thing we’ve built? A reputation.

True to you

Generations of care in craft.

This history is not taken lightly; every care is taken to maintain the tradition of hand-made, artisan focus through each stage of production. From sourcing leather and fabrics to constructing frames and sewing upholstery every cut, stitch or nail is undertaken with care.

Our close supplier relationships, carefully forged over these years, ensure we can source our materials from companies that parallel our devotion to the craft.

Discerning consumers recognise the difference investing in true luxury provides. That difference? The most comfortable, durable and timelessly stylish furniture you’ll own. From our factory, to your homes and businesses, our furniture is still made here, and still true to you.

For tomorrow

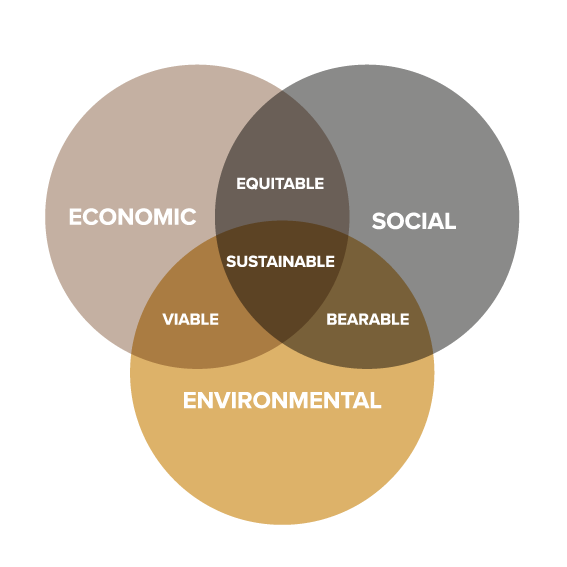

Our environmental responsibility

We continuously strive to make improvement in our sustainable practise, ensuring the lowest possible environmental impact and a future we can all be proud of. This approach combines both overall common sense and dedication with exceptional individual efforts and initiatives. It is an unwavering and unrelenting one – we are always looking at new ways to positively shape tomorrow.

Built to last

Our furniture is designed and built to withstand the test of time. When you invest in one of our pieces there’s a very good chance it will be enjoyed by the next generation too, diverting unnecessary material from the waste stream in the process. By using precision componentry and quality materials we make durability in design and construction a key priority. By choosing one of our pieces, you make the choice to step away from a throwaway culture, instead investing in lasting style and enduring comfort.

We offer the option of using New Zealand wool in your furniture – this natural approach provides sumptuous comfort while markedly reducing our carbon footprint.

At Kovacs we also use water-based solvent-free adhesives without environmentally harmful VOCs. This material and energy-saving system ensures minimum quantities saving valuable raw materials. Our adhesive is odourless, non-yellowing and aging resistant. We are continuously working to minimise and eliminate plastics within our manufacturing processes.

Kovacs frames are predominantly made from indigenous silver beech from Southland’s natural and second-growth forests. These privately owned forests must prove that they are managed to precise standards as part of a detailed and long-term sustainability plan. This involves the forestry gaining a Ministry of Agriculture and Forestry approved Sustainable Forest Management (SFM) Plan or SFM Permit.

Reducing and managing waste

During manufacturing processes various measures are taken to ensure the environmental management of all waste materials. Wood working machines are equipped with vacuum sawdust collecting facilities, which ensure a clean working environment. Scrap metal is collected and is recycled where possible. Packaging materials are reduced to a minimum carefully sorted and quickly recycled. We also recycle Dacron into the community, where it is used for various different projects.

The journey to you

Our sustainable efforts don’t stop in the production of our furniture. So too do we always look to minimise and mitigate any impact on the environment as Kovacs furniture makes its way to you. There are a huge number of ways the logistical processes involved with packaging and shipping can be positively influenced – and we’re always seeking to evolve and improve this process.

Our raw material

At Kovacs our furniture leathercraft focuses on sourcing, assessment and careful placement of the various grades.

No two hides are ever quite the same – which means every piece of furniture using this material is absolutely unique.

Get up close to good leather and you’ll see the difference. It’s the smell, texture, the touch and look of quality that sets a high-end piece apart. Cheap ‘processed’ stock does not feel like this. However nor are the most expensive leathers necessarily the most practical for furniture in some environments.

With semi-aniline leather there’s a minimal amount of processing, the light coating ensures some protection from soiling while still retaining a natural feel. It’s how we gain the balance of luxurious touch and longstanding toughness.

We have used the same Italian tanneries for two decades now. Back then we were drawn to their passion and commitment to the craft. Today they’re still absolutely dedicated to producing the highest quality leathers.

Each hide naturally has durable thick areas and other, more delicate places that can stretch further. Assessment is a simple but exacting process. The different furniture zones play a big part in placement. There are wear zones, visible zones, creases and hidden spots. Trying to get the right balance is not a science, but an art.

First each hide is stretched to identify any imperfections. Then the patterns are marked and graded for different areas. Working with it is a very tactile experience – it rewards those who know what they’re doing.

Buying leather furniture can be similarly rewarding, as the true nature of this material will reward you for decades after purchase. For the educated furniture purchaser this enduring style and comfort is worth every cent.

Any New Zealand furniture maker worth their salt should prove their wood comes from a sustainable source. We’re proud our furniture is grown here.

We use indigenous silver beech from Southland’s natural and second growth forests. These privately owned forests must prove they are managed to precise standards as part of a detailed and long-term sustainability plan. This involves the forestry gaining a Ministry of Agriculture and Forestry approved Sustainable Forest Management (SFM) Plan or SFM Permit.

This wood is strong, hardwearing and provides a smooth canvas for high quality finishes. At Kovacs frames are hand-cut, then glued, screwed and corner-blocked for sturdiness. Details are finessed and the pieces assembled to create the final chassis. This process takes time – quality craftsmanship always does.

At Kovacs frames are hand-cut, then glued, screwed and corner-blocked for sturdiness.

We think it’s worth it. Dig beneath the surface it’s easy to see why some mass-market furniture is so cheap – it’s often constructed with international timber from ecologically damaging sources. We make furniture for future generations to enjoy. Which is why we use high-quality New Zealand timber from environmentally sustainable sources.

Using Wisewool is much about common sense as it is exceptional capability.

Humans have known about the natural benefits of wool for centuries, with early use dating back to 10,000BCE. While there are many alternatives in the modern era, wool is still celebrated as a naturally breathable and flexible material, making it ideal for many different roles in a variety of industries.

Much of the natural assets of wool make it the perfect padding material for furniture. Its resilience and elasticity means it will bounce back quickly and easily when pressure is applied and, similar to its performance for clothing, it also has the ability to regulate temperature. Add to this the fact that wool is naturally fire resistant and, so long as there are sheep in New Zealand, a completely renewable resource, and it becomes a clear, smart choice for our furniture and for our planet.

We offer Wisewool as an option to many of our models to provide a buffer between springing and foam – a soft protective layer between foam and fabric and as an internal fill for cushioning. Made in Gisborne and Waikato, Wisewool offers three products of different densities: cushion fill Wisewool Cloud, denser loose fill Wisewool Buds, and Wisewool needle punched blanketing.

At a hefty 150gsm-1250gsm weight, Wisewool’s blanketing product is of particular interest for upholsterers. It comes in a 2.4m wide roll of varying lengths and thicknesses, and boasts a high level of tear resistance.

Kovacs is proud to be using this locally grown and manufactured product and to be supporting a New Zealand company, while also ensuring our furniture is the best it can possibly be.

CONTACT US.

Sign up to our newsletter, like us on Instagram and follow us on Facebook for updates and promotions.

SUBSCRIBE.

Kovacs Design Furniture

© 2021

Christchurch

Factory and Showroom

1000 Ferry Road

Ferrymead, Christchurch

03 384 2999

[email protected]

Showroom viewing by appointment only - please phone 03 384 2999

Auckland

Trade Showroom

159 Design

159 Great North Road,

Grey Lynn

Auckland

Open 8.30 – 5.00pm weekdays

09 309 5553 or 027 493 6004

[email protected]